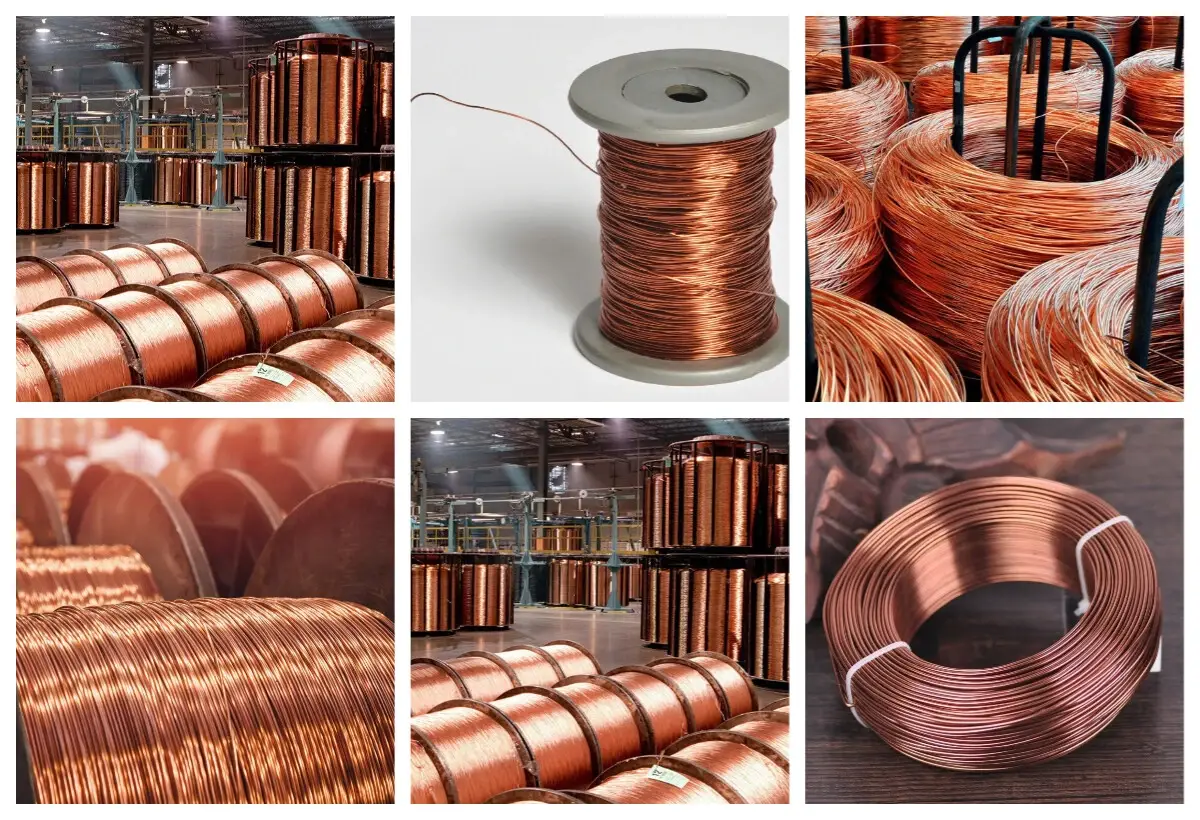

T2 purple copper wire red copper wire conductive purple copper wire diameter 0.5mm 0.8mm 1.2mm

Copper is industrial pure copper with a melting point of 1083°C, no allotropic transformation, and a relative density of 8.9g/cm3, which is five times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Because of its rose red color and purple color after the oxide film is formed on the surface, it is generally called red copper. It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper. The impurities in it are oxidized and discharged, and the amount of solid solution is reduced, which is beneficial to the electrical conductivity of copper and can also eliminate the influence of harmful impurities. However, copper is prone to embrittlement (known as hydrogen disease) in reducing atmospheres above 370°C. There are three grades of copper in my country: T1, T2, and T3, of which T2 copper is widely used. T1, T2, T3 copper is divided according to the different chemical composition. The copper content of T1 red copper is more than 99.95%, and the sum of impurities does not exceed 0.05%; the copper content of T2 red copper is more than 99.90%, and the total impurity content does not exceed 0.1%; the copper content of T3 red copper is more than 99.7%, and the total impurity content does not exceed 0.3%. .

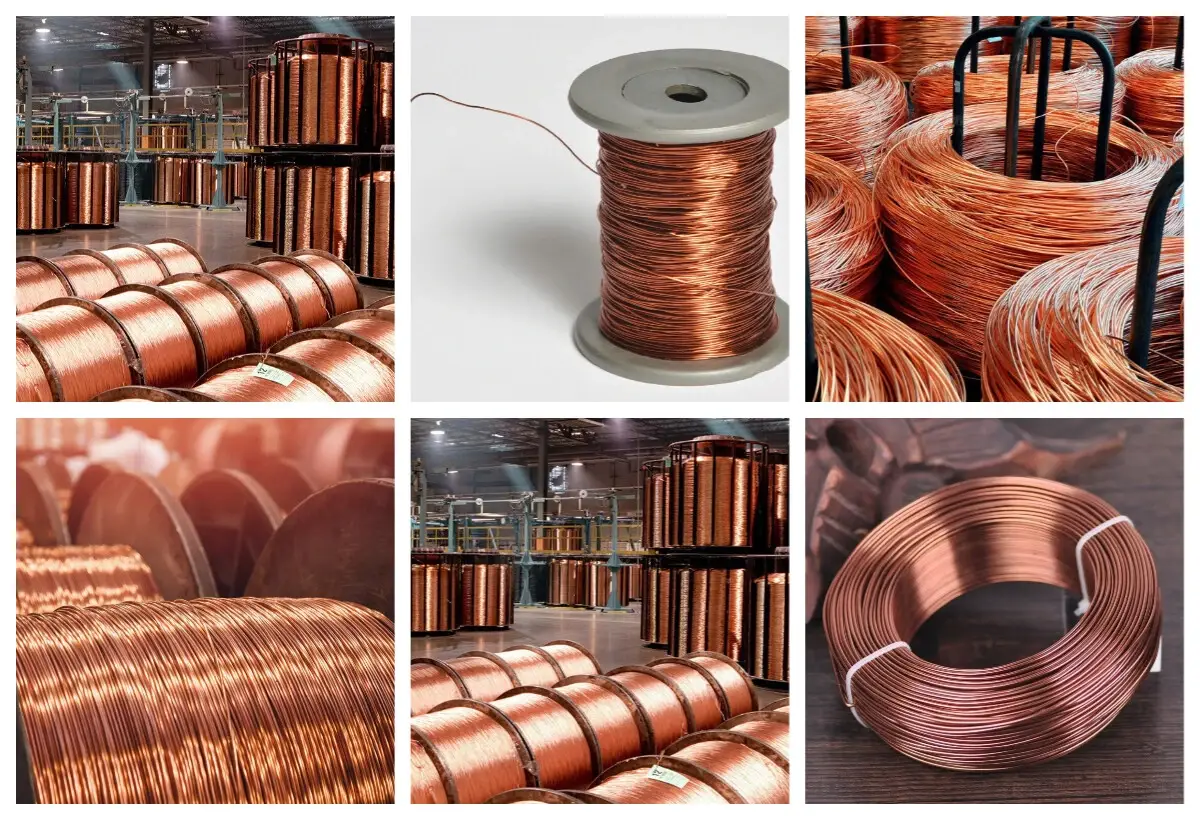

high quality round red copper stranded wire braid copper wire factory direct

Copper is industrial pure copper with a melting point of 1083°C, no allotropic transformation, and a relative density of 8.9g/cm3, which is five times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Because of its rose red color and purple color after the oxide film is formed on the surface, it is generally called red copper. It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper. The impurities in it are oxidized and discharged, and the amount of solid solution is reduced, which is beneficial to the electrical conductivity of copper and can also eliminate the influence of harmful impurities. However, copper is prone to embrittlement (known as hydrogen disease) in reducing atmospheres above 370°C. There are three grades of copper in my country: T1, T2, and T3, of which T2 copper is widely used. T1, T2, T3 copper is divided according to the different chemical composition. The copper content of T1 red copper is more than 99.95%, and the sum of impurities does not exceed 0.05%; the copper content of T2 red copper is more than 99.90%, and the total impurity content does not exceed 0.1%; the copper content of T3 red copper is more than 99.7%, and the total impurity content does not exceed 0.3%. .

High Temperature Super Enameled Swg 35-36 Round Enamelled Copper Wire Manganin Wire

Copper is industrial pure copper with a melting point of 1083°C, no allotropic transformation, and a relative density of 8.9g/cm3, which is five times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Because of its rose red color and purple color after the oxide film is formed on the surface, it is generally called red copper. It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper. The impurities in it are oxidized and discharged, and the amount of solid solution is reduced, which is beneficial to the electrical conductivity of copper and can also eliminate the influence of harmful impurities. However, copper is prone to embrittlement (known as hydrogen disease) in reducing atmospheres above 370°C. There are three grades of copper in my country: T1, T2, and T3, of which T2 copper is widely used. T1, T2, T3 copper is divided according to the different chemical composition. The copper content of T1 red copper is more than 99.95%, and the sum of impurities does not exceed 0.05%; the copper content of T2 red copper is more than 99.90%, and the total impurity content does not exceed 0.1%; the copper content of T3 red copper is more than 99.7%, and the total impurity content does not exceed 0.3%. .

Copper Wire Swg Cca Purity Occ Red Copper Wire Winding Pure Super Copper Wire Price

Copper is industrial pure copper with a melting point of 1083°C, no allotropic transformation, and a relative density of 8.9g/cm3, which is five times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Because of its rose red color and purple color after the oxide film is formed on the surface, it is generally called red copper. It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper. The impurities in it are oxidized and discharged, and the amount of solid solution is reduced, which is beneficial to the electrical conductivity of copper and can also eliminate the influence of harmful impurities. However, copper is prone to embrittlement (known as hydrogen disease) in reducing atmospheres above 370°C. There are three grades of copper in my country: T1, T2, and T3, of which T2 copper is widely used. T1, T2, T3 copper is divided according to the different chemical composition. The copper content of T1 red copper is more than 99.95%, and the sum of impurities does not exceed 0.05%; the copper content of T2 red copper is more than 99.90%, and the total impurity content does not exceed 0.1%; the copper content of T3 red copper is more than 99.7%, and the total impurity content does not exceed 0.3%. .

Pure Copper Wire 99.94% Min Supply Non-Ferrous Metal Bare Copper Wire

Copper is industrial pure copper with a melting point of 1083°C, no allotropic transformation, and a relative density of 8.9g/cm3, which is five times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Because of its rose red color and purple color after the oxide film is formed on the surface, it is generally called red copper. It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper. The impurities in it are oxidized and discharged, and the amount of solid solution is reduced, which is beneficial to the electrical conductivity of copper and can also eliminate the influence of harmful impurities. However, copper is prone to embrittlement (known as hydrogen disease) in reducing atmospheres above 370°C. There are three grades of copper in my country: T1, T2, and T3, of which T2 copper is widely used. T1, T2, T3 copper is divided according to the different chemical composition. The copper content of T1 red copper is more than 99.95%, and the sum of impurities does not exceed 0.05%; the copper content of T2 red copper is more than 99.90%, and the total impurity content does not exceed 0.1%; the copper content of T3 red copper is more than 99.7%, and the total impurity content does not exceed 0.3%. .

Factory Price Custom Size Pure 99.9999% 0.8 Mm Enamelled Copper Wire

Copper is industrial pure copper with a melting point of 1083°C, no allotropic transformation, and a relative density of 8.9g/cm3, which is five times that of magnesium. The mass of the same volume is about 15% heavier than ordinary steel. Because of its rose red color and purple color after the oxide film is formed on the surface, it is generally called red copper. It is copper containing a certain amount of oxygen, so it is also called oxygen-containing copper. The impurities in it are oxidized and discharged, and the amount of solid solution is reduced, which is beneficial to the electrical conductivity of copper and can also eliminate the influence of harmful impurities. However, copper is prone to embrittlement (known as hydrogen disease) in reducing atmospheres above 370°C.

Brass Inserts

The wide range of Brass Inserts include threaded molding inserts, ultrasonic molding inserts, knurled molding inserts, molding inserts for plastic, wood molding inserts and more. The range of standard and high quality molding inserts designed to molded into the plastic, wood or any molded components.

CNC Machined Components

CNC Machined Parts is a type of machining that will create very precise and accurate products. the method of shaping a spinning workpiece into the desired shape by removing material with cutting tools. CNC turning machining has many advantages including high precision, repeatability, increased productivity, reduce setup time, and versatility. This method is used in a making variety of metal products brass, copper, steel, aluminum, and bronze. The choice of material will depend on applications and requirements. CNC precision turning parts are widely used in many industries, including electrical, defense, medical, aerospace, and automotive.

Brass Turned Components

We are engaged in offering a wide range of Brass Turned Components to our clients at a reasonable cost. Our turned components are made using quality raw material such as high and fine grade brass to assure quality and reliability. We manufacture all types of Brass turned components depending upon client’s requirement for application in any industry. The range of Brass Turned Components find wide application in machine building, automobile, hydraulics and general engineering industry. Our turned components are tested on numerous parameters to assure it on counts of quality.